When fishing with a reel, the line is repeatedly released, or fed, from the spool and rewound.

With PE lines, the most common problems that come to mind are thread twisting, biting into the line wound on the spool reel, knotting (tangling in the guide ring or not passing through it properly) and forming small bumps (small knots).

These are mostly caused by line not being released, fed, or rewound normally, but some problems are easier to prevent than others.

Line twisting cannot be avoided when contraptions or lures spin, or a fish whirls about. Although spinning reels have evolved, they will inevitably get a line snag due to their structure, and not all reels are designed for PE lines.

On the other hand, some problems, such as line biting into the spool, knotting, forming bumps, and associated snapping, are relatively easy to prevent.

When we ship and deliver spooled lines, we only apply the minimum amount of tension possible to the spool so that it is “softly wound.” This ensures the line is delivered to users in the best possible condition.

The key to reeling such lines is to avoid unnecessary damage and wind the right length at the right tension for the target fish (and its fishing).

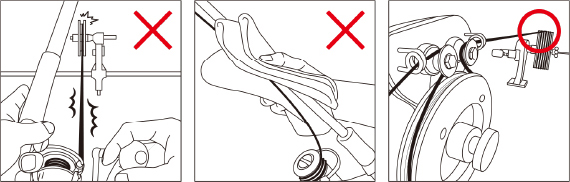

Firstly, the correct tension. There is absolutely no need to wind with more force than the expected drag setting. And no direct force should be applied to the spool. Depending on the line thickness, the trick is to wind it with one fulcrum point via a finger or guide.

Secondly, wind at a constant speed. The strain on the line varies greatly from the beginning to the middle of winding. Just as the strain on your legs changes when you start pedalling a bicycle and after you gain speed, there will be a tension difference if you change speed or stop in the middle of winding. And when winding, do not let the line chafe too hard. Minimise the areas where the line comes into contact and remember that guides and fingers are only “aids” when used.

Heat is the bane of fishing lines in general. It is no exaggeration to say that if you sense the line is hot while reeling it in, it’s already too late, as it would have reached 80 to 90 degrees Celsius. In other words, it points to significant deterioration.

For example, many of us have experienced slipping on the gymnasium floor in gym clothes while chasing a ball as children. It is not unusual to feel the heat to find that the fabric had melted at the knees, but the melting point of the polyester used to make gym clothes is about 270 degrees Celsius. In comparison, the melting point of high-molecular-weight polyethene, the material used to make PE lines, is about 150 degrees Celsius.

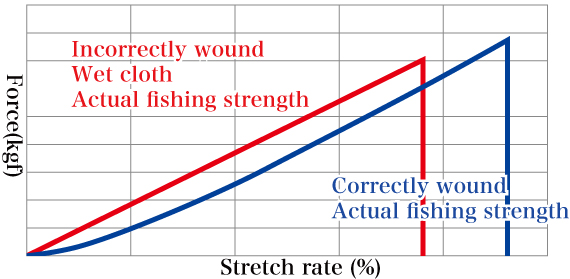

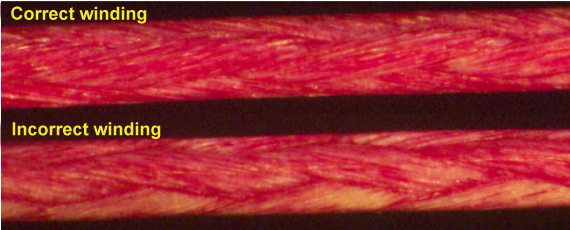

This means that damage from heat and abrasion can cause the PE line fibres to perform worse than expected. No matter how strong the material is compared to nylon or fluorocarbon, it is meaningless if the performance is one or more grades lower than indicated.

In reality, however, lines are incorrectly reeled in far too often.

For example, the most common is to reel the line while applying a lot of tension directly onto the spool. As mentioned before, the line is wound with the minimum amount of tension possible, so when a lot of tension is applied, the line will bite into the spool and sometimes snap.

We sometimes receive complaints about product issues when transferring a spool onto another reel spool, but a closer investigation reveals that, in most cases, the spool has been wound in a very damaging way.

However, the best practical approach for thin lines thinner than No. 1 would be to softly wind the line from the spool to the spool reel.

Contrary to the previous example, the second most common error is reeling in the line with insufficient tension. It can cause the line to bite into the spool reel when the drag is triggered, and the line is released during actual fishing.

The third, often the case when targeting large fish, is to wind the reel with excessive tension for fear of biting into the spool reel. It causes imbalance and flattening of the PE line braid, reducing the actual fishing strength, and causing guide squeal.

The fourth is storing more line than the correct amount on the spool reel. The braiding of the PE line can accidentally cause it to exceed the correct level and form knots as the line extends and contracts (≒swelling) with use. Particular attention should be paid to this in the case of spinning reels.

The last error is reeling in the line while holding it with a gloved hand or a towel. Even when wet, its adverse effects remain the same, with the surface coating peeling off and feathering causing problems.

The PE line is adjusted and manufactured to ensure an exact braid. Appropriate surface coatings are also applied to suit the fishing method.

Incorrect handling can turn a good product into a faulty product, but unfortunately, this kind of handling is common practice amongst the public.

There are even examples of mass retailers routinely using a wet towel to wind up the line while applying a lot of tension or even line manufacturers uploading official videos of how it is done.

The best conceivable way to get a PE line onto a spool reel in the best possible condition is to use a dedicated machine, but only a few specialised shops are equipped with these. Such machines on the open market are also expensive and uncommon. In addition, none of them are designed to be 100% anti-abrasion. It is truly regrettable.

“If the cause is known, it should be addressed by the line manufacturer”

That may be so, but we want to offer high-quality lines at affordable prices. If that is the case, we can only wind the spools with minimal tension when shipping.

For example, a significant change in the spool's design might solve the problem but lead to a significant price increase. If the line is wound onto the spool with a lot of tension at shipping, the issue will be dramatically reduced, but on the other hand, the line quality will suffer significantly.

Be that as it may, unless you understand the condition in which our PE lines are shipped, it will be difficult for you to fish with them in the best condition. We can assure the line's quality when shipping, but it is up to the user to ensure it is in good condition during fishing.

In other words, true line quality is achieved not only by the manufacturer but also by the angler... That is how we see it.